3D Printing Uses Within the Racing Industry

Share

Every advantage counts in motorsport. With the highest technological advancements and innovation methods, teams are looking to additive manufacturing to enhance their capability on the track.

There are many factors that go into improving a race car. With aerodynamic efficiency, engine reliability, tyre composition and the pit service schedule all need fine-tuning - 3D printing has an ever-growing part to play in this.

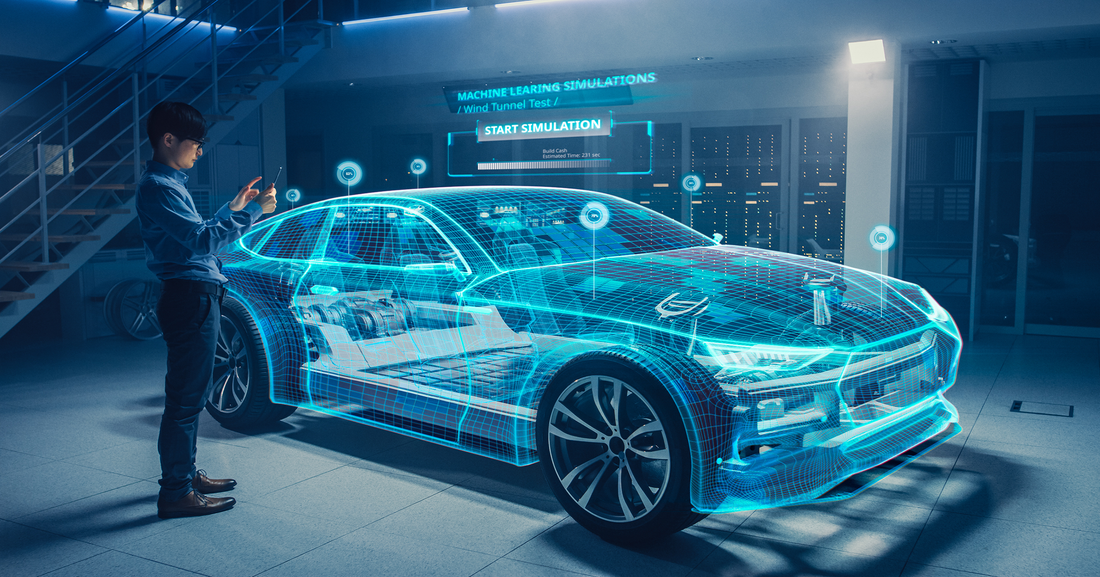

Rapid Prototyping is a common buzzword for 3D printing. Either scale vehicles or their subcomponents are printed to run tests to see how they might perform on the track. From producing small-scale models for wind tunnel testing to being the aid in tooling and jig design.

Thanks to 3D printing technologies, slight modifications to improve the design can be analysed almost straight away. This can be anything from metal chassis components, exterior body panels, engine and powertrain components and cast metal parts replicated using 3D printing techniques.

Best of all, 3D printing opens new avenues for parts that were previously impossible to manufacture. Paving way for whole new designs and shapes that can be formed using 3D printing methods.

Materials play a big part in the motorsport industry too. If a lighter material can be used or removed altogether, then 3D printing can quickly analyse the differences in components to see which is the most efficient design.

The Evolving Future of Motorsport

Climate change is a big topic in the world today. With government organisations helping reduce carbon emissions, motorsport is trending towards less use of combustion power too. Instead, teams and divisions are turning to hydrogen and electric-powered machines.

Taking 3D printing to help with the high current, pressures and reducing weight in these evolving areas shows a bright future for the industry. As motorsport typically filters down to road going vehicle technology, it could be just a short while before we see a lightweight 3D printed component in our everyday cars.

The latest season of motor racing has seen Ducati in Motorbike Racing, NASCAR and Alfa Romeo all pairing with 3D printing companies - naming them as their strategic partner.

Reducing lap times and weight are the two main components in motor racing, and big teams are latching on to the fact that 3D printing helps with these.

With the everchanging rule book of Formula 1, the FIA’s latest amendment invalidated wings that had been 3D printed to be used in this year’s racing. Companies and teams have pivoted to produce brackets, seals and internal components from 3D printing methods instead.

Real-World 3D Printing Examples in Motorsport

Formula 1

Williams Martini Racing team use 3D printing in their front wing design. To constantly iterate and improve, they needed a method to quickly produce their latest concept. Whilst also need to be a cost-effective method

Motorcycles

Pankl Racing Systems is an Austrian-based company that supplies systems to the motorsport industry. They produce parts that would not otherwise be possible in traditional manufacturing methods. They relish the quick rapid prototyping process to produce parts for their customers.

Motorcycle footrests are an important part that a rider uses constantly in racing. To get the correct grip, lightweight design and material usage, additive manufacturing methods are used to produce an innovative solution.

NASCAR

The next generation of NASCAR vehicles is to be assembled with 3D printed parts. With collaborations from 3D printing companies, the windshield air cockpit ventilation unit is to be manufactured this way.

Road Cars for the Track

Toyota Racing Development (TRD) division has partnered with a 3D printing house to tune Toyota’s street cars using these methods. An example is the new Toyota GR86 production car having a 3D printed FDM Nylon 12CF hood vent.

With 3D printing at the forefront of motorsport technologies, it is being used more now than ever. Changes in rules and the overall advantages 3D printing gives may see its limited use cases in the future. As safety is also now a top priority in motor racing.

Future technologies such as Hydrogen Fuel Cells and Electric Motors could see new uses for 3D printing technologies, as we look to help reduce carbon emissions and drive more efficiently. Partnerships are popping up everywhere, as lightweight components are being manufactured in a way that has previously not been possible.

3D Printing Uses Within the Racing Industry Written by Alex Bull

Automotive Writer, Engineer and overall enthusiast. Feel free to get in touch click here