Welcome to our latest blog post where we delve into the common challenges of SLA (Stereolithography) 3D printing and provide you with essential tips to ensure your prints come out perfectly every time. Whether you're a beginner or a seasoned pro, following these guidelines can help you avoid the frustration of failed prints.

Level the Print Bed

One of the most critical steps in SLA printing is ensuring that the print bed is perfectly level. An uneven bed can lead to poor adhesion of the first layer, causing the print to fail or parts of it to not form correctly. Make sure your print bed is level and that the build platform is correctly calibrated to the correct height relative to the resin vat.

Ensure Optimal Bed Adhesion

Improving the first layer's adhesion is crucial, especially for intricate prints. For SLA printing, ensuring the build platform is clean and properly prepared is key. Sometimes, lightly sanding the build platform can increase adhesion.

Control the Temperature

Temperature stability is important in SLA printing to ensure the resin behaves consistently. Too much fluctuation can affect how the resin cures, which might lead to failed parts or inaccuracies. Keep your printing environment at a consistent temperature to avoid these issues.

Use Quality Resin

The quality of your resin will directly impact the success of your prints. High-quality resin ensures consistent curing and reduces the risk of failed prints. Always store your resin in a cool, dark place to maintain its quality and prolong its shelf life.

Adjust Print Speed and Exposure Settings

The speed at which you print and the exposure settings for curing the resin can also affect the outcome. It's important to find the right balance between exposure time and layer height for the specific resin you are using. Consult your resin manufacturer's guidelines to set the right parameters.

Incorporate Support Structures

For models with overhangs or complex geometries, adding support structures is necessary in SLA printing. Supports help to stabilize the print and prevent parts of it from failing during the printing process. Properly planning and placing supports can make a significant difference in print success.

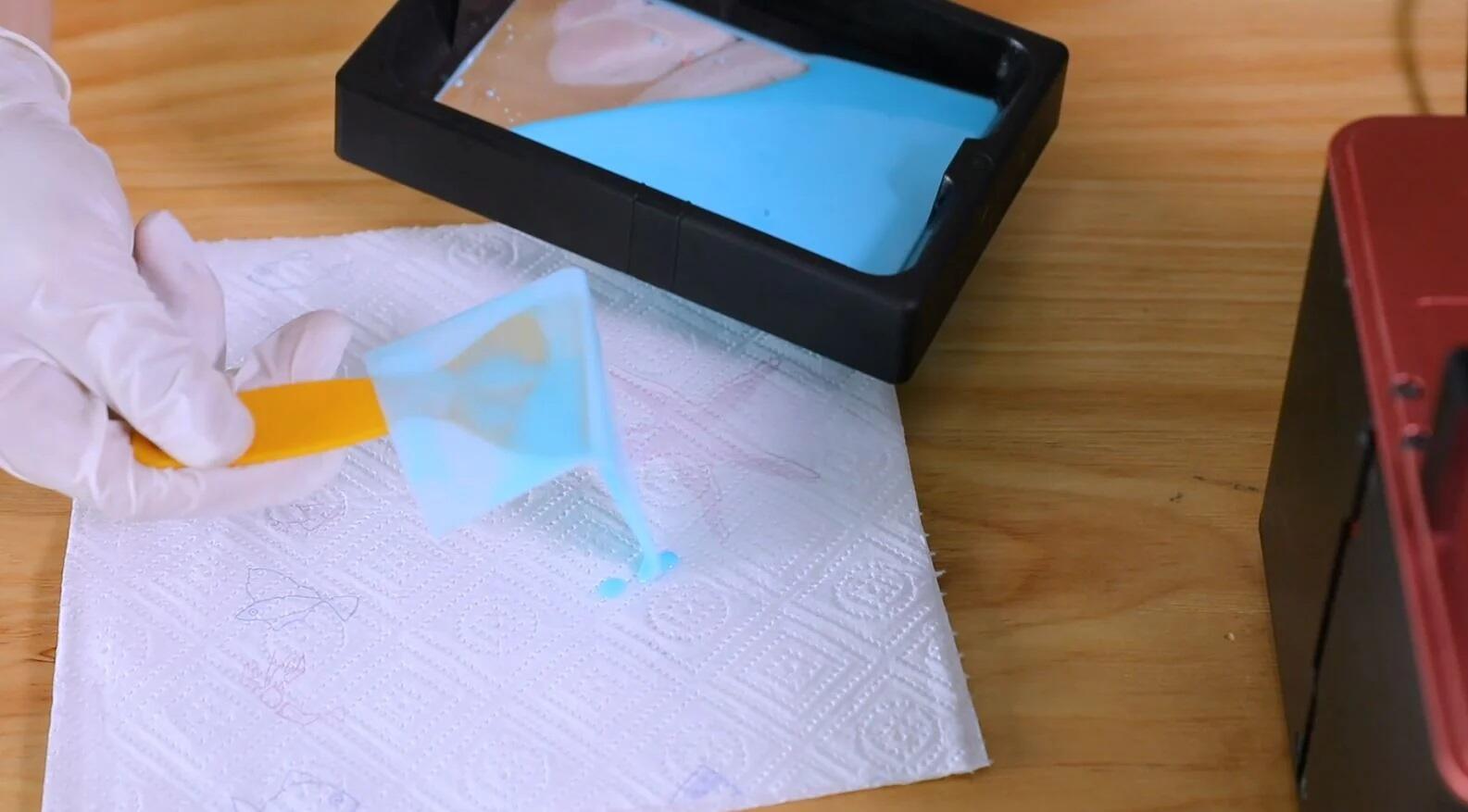

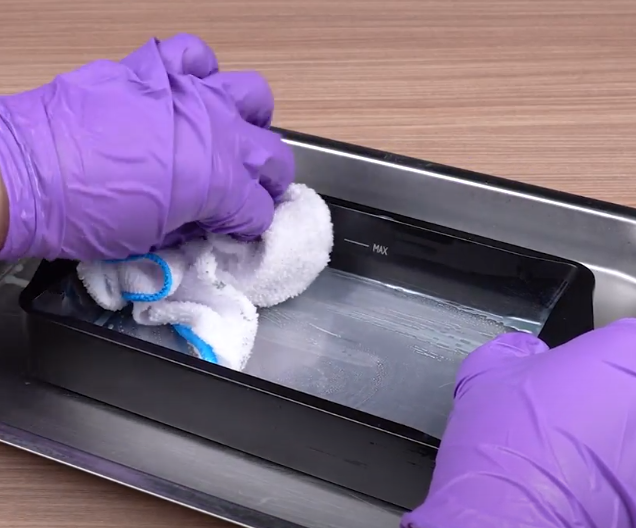

Maintain Your Printer

Regular maintenance is key to consistent print quality in SLA printing. This includes keeping the resin vat clean, ensuring the UV light source is functioning properly, and regularly checking the mechanical parts for any signs of wear or needed adjustments.

Optimize Slicing Software Settings

Finally, the settings in your slicing software can make a significant difference in print quality. Parameters like layer height and cure times should be tailored to each specific print and type of resin. Experiment with different settings to find what works best for the object you are printing.

By following these tips, you can greatly reduce the likelihood of print failures and improve your overall success rate in SLA 3D printing. Happy printing!